Using Variable Air Volume (VAV) Systems to Lower Energy Usage in HVAC Systems

2023-08-10 09:00

Variable Air Volume (VAV) is a type of HVAC system that preserves a constant temperature while fluctuating the airflow intensity to heat or cool buildings. This is contrary to the way Constant Air Volume (CAV) systems work; CAV systems supply a constant airflow while the temperature of air changes.

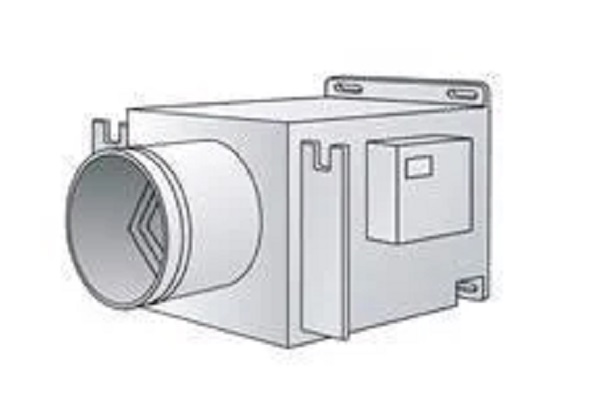

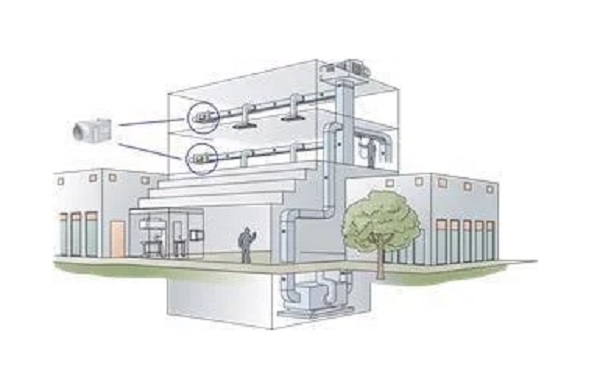

The below example shows how such a VAV system works.

An air handling unit drives air into the HVAC duct system at a constant temperature, for instance, at 13 °C. This air temperature remains constant throughout the HVAC system, moving through each zone of the building’s ductwork.

As the air passes through each zone, it flows across a VAV box or terminal, which varies the airflow into the zone in accordance with the thermostat setting of that area.

In addition to a damper that changes to regulate airflow, most VAV boxes also contain a heating element for warming the air as necessary.

According to the requirements of each specific zone, the VAV terminal modulates temperature. This enables more efficient control as the HVAC system provides various temperatures and fan speeds throughout the system to meet the needs of the individual zones. The added control of VAVs offers a number of extremely important benefits:

More precise temperature control: In contrast to a CAV system that runs the fan and compressor at full capacity in an on/off cycle, a VAV system consistently varies the fan speed to sustain a constant air temperature.

Reduced compressor wear: As a VAV system modulates the control of the compressor, its wear and tear is reduced over the long term.

Lower energy consumption by system fans: VAV fan control, particularly with electronic variable speed drives, leads to an energy consumption reduction which is a significant part of the total cooling energy costs of a building.

Less fan noise: CAV systems run fans at maximum speed and turn them on/off constantly, resulting in considerable noise compared to a VAV system that runs at a more constant, lower speed fan at a reduced decibel level that can easily blend into the background.

Increased dehumidification: The air is dehumidified as the VAV system exposes air to cooling coils longer than CAV systems, with more moisture condensing on the coils.

The Role of Differential Pressure Sensors in VAV

As VAV systems are able to sustain a constant temperature and vary the airflow to reach the desired conditions, differential pressure sensors play a central role in their function.

In particular, the sensors are able to measure the volume of air across two points and supply the control system with appropriate feedback to open or close dampers to preserve the temperature required in each of its zones.

While differential pressure sensors are a key component of VAV systems, they are vulnerable to external factors that can influence performance.

For instance, fans and blowers produce significant amounts of noise and vibrations that can affect the sensor’s accuracy. Filtering out that noise prior to it reaching the sensing element will significantly improve accuracy.

A crucial consideration to bear in mind when installing sensors in a complex system is the necessity to maintain long-term stability, as replacing sensors or VAV units is labor-intensive and can be expensive, particularly in larger HVAC implementations.

Finally, as the different zones of the ‘air network’ may have varying requirements (e.g., an interior lab or server room vs. a window facing conference room), the capability to have one differential pressure sensor that can fulfill all the different pressure requirements will streamline the overall system design and simplify VAV device inventory management.